WAM-100, WAM-120 & WAM-125BB

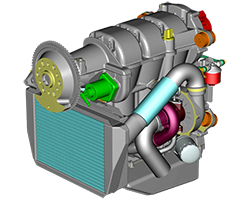

Configuration: 3 cylinder, 2-stroke, compression ignition, liquid cooled engine of inverted configuration with pressure fed lubrication and integral sump.

Configuration: 3 cylinder, 2-stroke, compression ignition, liquid cooled engine of inverted configuration with pressure fed lubrication and integral sump.

Forced induction: by turbocharger compressor to an intercooler, from which air passes through an integral blower to the engine cylinders and is thence exhausted through the turbocharger turbine.

Combustion system: low noise, clean burn, IDI; fuel injection is by a high pressure pump, lines and injectors; timing is factory set and adjustment is not required.

Valve gear: cam timing is factory set; the under-head camshaft is pressure fed with oil and operates 2 exhaust valves per cylinder via bucket tappets and shims; checking and adjustment via removable sump.

Cooling system: a gear driven pump circulates coolant through the engine and radiator, that can be mounted under the nose; an in-line thermostat provides temperature control.

Electrics: light weight, geared, permanent-magnet starter motor with pre-engaging solenoid. Automotive glow plugs. 12V, 30/40A alternator, with internal regulator.

Fuel system: an integral low pressure lift pump supplies fuel via an engine mounted fuel filter to a high pressure, engine oil lubricated, injection pump, with a return circuit to tank. Feed and return connections both AN-6.

Controls: Mechanical Control Unit (MCU) controls and stabilises engine fuelling and provides torque demand lever. Separate lever for engine shut-down. Torque and shut-down controls are both by standard aircraft type cables. A clevis fitting to crimp onto piano wire type cables is available.

Accessory drives:

- AND20010 propeller governor drive pad, with oil transfer sleeve and drillings, feeds engine oil, controlled to the correct pressure by the governor, to the propeller flange.

- AND20000 drive pad on injection pump for vacuum pump, hydraulic pump or secondary alternator.

PERFORMANCE - WAM-125B (for WAM-100, WAM-120 please see the spec sheets...)

Power / Torque / Engine RPM / Specific Fuel Consumption

T.O. – max 5 min: 93 kW (125bhp) / 323 Nm / 2750 / 255gm/kW hr (0.42lb/HP hr)

Max. continuous: 75 kW (100bhp) / 275Nm / 2560 / 250gm/kW hr (0.41lb/HP hr)

Economy Cruise: 62kW (83bhp) / 247Nm / 2400 / 240gm/kW hr (0.395lb/HP hr)

Cruise fuel flow is typically 25-30% less than gasoline engines at the same power setting.

FUEL / OIL / COOLANT

Jet-A1 / 5W-40 synthetic (AeroShell Diesel) / Cool-Elf Supra premixed

Typical Installed Weights (kg) - with constant Speed Propeller

Engine exc cooling pack - 99.0

Cooling pack, Oil cooler and hoses - 7.0

Propeller MTV-21 - 11.5

Prop. Nuts Washers (1/2" nylocks) - 0.2

Jihostroj Governor/CSU 1.0 - 1.0

Coolant Bottle and hose - 0.6

Exhaust silencer and down pipe - 2.5

Oil (6 litres) - 4.8

Coolant (3.5 litres) - 3.5

Lord mounts and AN7 bolts - 1.6

Total: 131.7

Warning: This engine does not comply with national or federal safety regulations for standard aircraft. This engine is for use in non-certificated aircraft only, and only in circumstances in which an engine failure will not compromise safety. Become familiar with the operator’s manual before operating the engine. Refer to Wilksch Airmotive for further details.